- Home

- Micro Cabling Infrastructure Delivers Significant ROI

Stories

Micro Cabling Infrastructure Delivers Significant ROI

As the world opens up to the Post-COVID era, the transportation industry will focus on communications’ interoperability for all modes of travel – air, roads, sea and rail. Transportation communications interoperability has many facets. One example is to connect regions of tolling, such as E-Z Pass in the Northeast with SunPass in the Southeast. Another important change is to convert all toll systems to electronic tolling, which will eliminate human interaction and shield toll collectors and drivers from contagion. But, to accomplish that, there needs to be an efficient fiber optic infrastructure for access networks to address mass communications transportation.

Micro cabling is an innovative approach to installing an optical network. Blown fiber micro-cabling technology is quickly becoming the preferred fiber optic system solution for access networks based on bandwidth requirements, speed of deployment, network flexibility, future scalability, and of course, the lowest total cost of ownership. When compared to traditional fiber cabling, micro cabling systems provide a much higher return on investment (ROI) due to reduction in material costs, as well as the overall lower cost in labor capitalized by drastic reduction in installation time.

What is Micro Cabling?

Micro cabling through a blown fiber process uses compressed air or nitrogen to literally blow (or “jet”) lightweight optical fiber bundles or micro cables through predefined routes at rates up to 500 feet per minute. Micro cables are normally used in the feeder and distribution network which travel in small micro tubes and then are transitioned into fiber bundles in the last mile to connect to the end user.

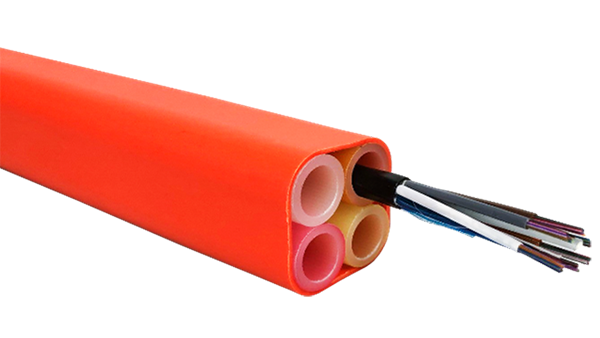

Micro cables allow for much higher fiber density in a given cross-sectional area of cable. These tube bundles contain color-coded cells or microducts through which the optical fiber bundles are blown. These micro tubes are manufactured of tough but flexible materials and are sized to accommodate up to 432 fibers or more per micro tube within a microduct, which can be installed above ground (aerially) or underground. Using couplers, installers connect individual micro cable cells together in tube distribution units, or junction boxes, to provide routes through which fiber is blown to achieve a splice-free, point-to-point installation. A splice-free installation improves overall system reliability, which further is enhanced because no strain is placed on the fiber during the installation process.

Microduct assembly for incremental installation of micro cables. The assemblies typical comes in configurations from one to seven microducts.

Micro Cabling vs. Traditional Fiber Optic Systems

Micro-cabling system deployments have rapidly gained popularity due to significant advantages this offers over conventional fiber optic cabling. Cost reduction and system benefits of blown micro cable systems over traditional fiber systems are attributed to: OSP material reduction, faster installation time, less fiber connection points, simplified repair and maintenance and a migration path for future evolving applications.

The choice of installing a blown fiber cable system has an even greater impact on the success and profitability of the project because installation properties influence the time taken and future maintenance requirements. Another advantage of blown fiber cable system over conventional fiber optic system is that it allows users to install only the fiber needed to accomplish the tasks at hand. By allowing more room in the tubes or installing more tubes at the onset, moves, adds and changes are easily made.

Moreover, smaller, lighter cables mean smaller, lighter transportation reels that can be moved and stored with a much smaller footprint. Alternatively, longer cable lengths can be accommodated on standard transportation reels. Longer delivery lengths can translate to longer blowing lengths and fewer splice points when the installation is designed properly.

Comparison of standard duct cable and micro cable

Proven Installation Benefits with Blown Fiber

A typical cabling project is usually divided into 80% labor and installation and 20% materials. The demand for blown fiber cable systems is increasing due to the streamlining of the installation process and optimizing the network’s quality and total cost.

Conventional cable pulling is time consuming and normally requires a crew of 3-4 installers. Blown fiber installations are carried out in a few minutes with normally 1-2 persons. With a proper air compression tool with an electric motor, one person feeds the fiber and the other receives it at the far end. Conventional fiber cable requires costly digging of trenches and in-building innerduct. The cost for trenching and installation of conduits has the highest uncertainty and depends on many parameters such as type of soil (grass, asphalt, stone, etc.), labor cost for different areas and, machinery and methods.

Traditional fiber cabling requires ultra-high counts of fiber strands to be installed up front due to the expense of the labor. Field splicing is drastically increased in the traditional design due to having to add intermediate fiber enclosures and splicing, which is avoided with microducting and blown fiber.

The benefits of blown fiber are numerous. Micro cabling is making its way across the country one toll at a time.

For more information, contact Mark Turner at Hexatronic.

Joining IBTTA connects you to a global community of transportation professionals, offering unmatched opportunities for networking, knowledge-sharing, and collaborative innovation in the tolling and transportation sector.

Follow IBTTA on social media for real-time updates on transportation trends and collaborative opportunities.